top of page

S-20-S2

Twin Spindle Multiple Rip Saw

■ Top And Buttom Multiple Rip Saw

TWIN SPINDLE CONFIGURATION

Thin Kerf

Productivity 15% Increase

Outstanding Features

■ Twin saw spindles configuration for increasing cutting thickness.

■ 125HP extra powerful motors on top and bottom spindles.

■ Accommodates wood thickness up to 250mm.

■ High precision link chain mechanism assures high straightness accuracy.

■ 4 rows anti-kickback fingers provides operator with comprehensive safety protection.

■ Rugged machine construction ensures maximum rigidity and stability.

■ Aluminum movable saw path board instead of bakelite.

■ PLC control with touch-screen for user-friendly operation.

Pneumatically Loaded Pressure Rollers

■ Each pressure roller is leaded by an individual air cylinder, that allows varying thickness of wood to be fed and cut without need of further adjustment.

■ 50mm stroke provides less resistance force in wood infeed.

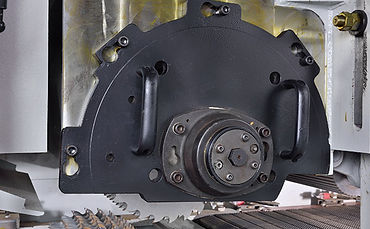

Twin Saw Spindles

Both top and bottom saw spindles are driven by extra powerful motor of 100HP (standard) or 125HP (optional), allowing the machine to perform heavy cutting with ease.

Hydraulic Bearing Housing Support

The externally mounted hydraulic bearing housing support provides convenience in sawblade replacement.

Durable Link Chain

■ The link chain blocks are manufactured from casting steel for maximum wear-resistance and long service life.

■ The link chain provides extremely stable wood feed and high straightness accuracy.

Powered Side Pressure Infeed Roller

■ The additional infeed roller makes wood infeed easier.

■ Available for online operation in a production line.

■ 1HP motor drive.

Pneumatically Locked Saw Carriage

The saw carriage is locked to the machine structure, that provides higher stability and leads to higher machining accuracy.

TWIN SPINDLE CONFIGURATION

-

Powered height adjustment for saw arbor

-

Powered height adjustment for pressure mechanism

-

Powered side pressure infeed roller

-

100HP motor

-

Servicing tools

-

Infeed fence

-

Sleeve and spacers

-

Infeed fence

-

Operation manual

Pine Precision Machinery Co.

ADDRESS : No. 302, Sec. 2, Tanfu Rd., Tanzi Dist., Taichung City 427, Taiwan (R.O.C.)

TEL : +886 4 2535-2112

FAX : +886 4 2535-2118

E-MAIL : pinemac@pinemac.com.tw

bottom of page